Table Top Fume Hood

Table Top Fume Hood Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Table Top Fume Hood

The Table Top Fume Hood is a top-of-the-line laboratory equipment designed specifically for industrial use. Made from high-quality mild steel, this fume hood is built to last and provide maximum protection to users. It features a metal construction that can withstand even the toughest environments, ensuring long-term use with minimal maintenance. With a warranty of 1-2 years, customers can be assured that they are investing in a durable and reliable product that comes with manufacturers guarantee. Designed to meet a wide range of laboratory needs, the Table Top Fume Hood is perfect for chemical storage, testing, and research applications. It provides safe and efficient ventilation, preventing harmful fumes and chemical particles from escaping and contaminating the laboratory environment. The product specification includes a front-mounted control panel, which makes it easy to operate, and provides total control over fume hood operation. Overall, the Table Top Fume Hood is an essential piece of equipment for any laboratory looking to maintain a safe and healthy work environment for its staff and to ensure valid test results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lab Furniture Category

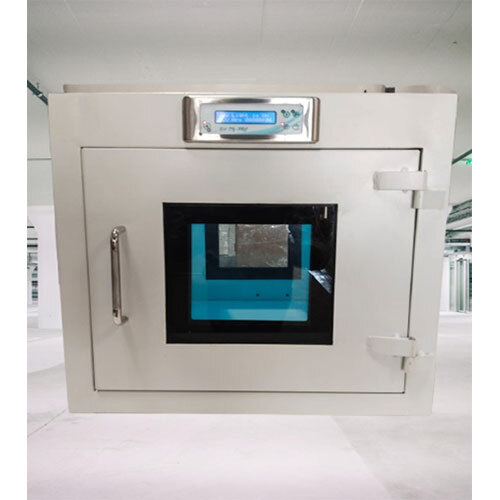

STATIC PASS BOX

Price 30000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Attractive Designs, Fine Finishing

Material : Stainless steel

Application : Industrial

Chemical Storage Rack

Price 25000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : high Quality

Material : Stainless Steel

Usage : Offices & Library

DISPENSING BOOTH

Price 284000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Attractive Designs, Fine Finishing

Material : Stainless steel

Application : Industrial

ISLAND TABLE

Price 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Durable

Usage : Laboratory

GST : 36GMOPM4383N1Z2

Send Inquiry

Send Inquiry Send SMS

Send SMS